In the paper industry there is a demand for innovations that reduce operating costs and help conserve resources in the production process. Voith developed its BlueLine range to meet both these requirements. Strong sales in the two years following the market launch of this product range confirm that this approach is appreciated in the industry.

In the meantime, more than 40 IntegraGuard headbox screens have been sold. The machine head geometry was flow-optimized to keep the flow velocity through the screen consistent and low, which prevents strings and deposits. Thanks to the new improved head piece of the screen, the energy requirement of IntegraGuard could be reduced and pulsation minimized. As a result, energy efficiency and paper quality are improved.

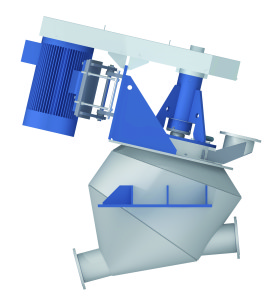

The most successful machine in the BlueLine range to date is the IntensaMaXX pulper detrashing machine, which has now had over 50 installations. This rugged machine has an asymmetric housing that prevents tail formation and stringing, so that even stock containing a lot of contamination does not cause problems in operation. In the IntensaMaXX, the reject is discharged in a downwards direction, ensuring reliable removal of all contaminants. IntensaMaXX can be used in all LC and HC pulping systems for recovered paper. Another advantage of the IntensaMaXX is its low energy consumption.